Electrical Safety For Managers

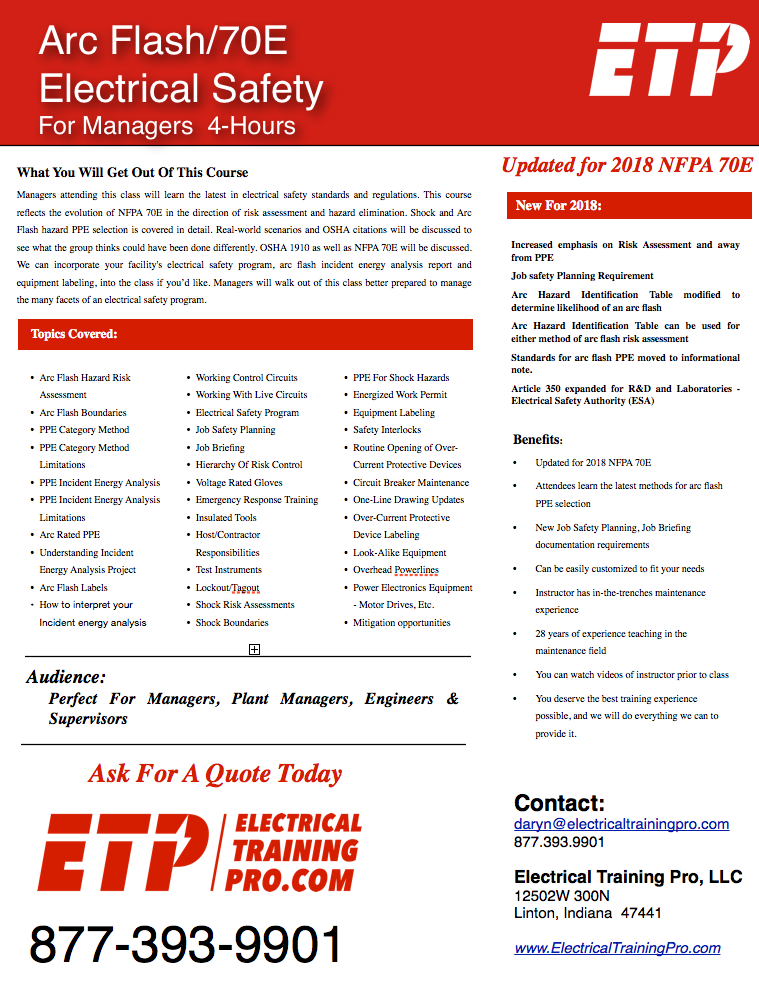

This training includes OSHA 1910 and NFPA 70E electrical safety requirements, and is specifically designed to help management personnel provide a safe workplace. Developing and implementing an electrical safety program that is effective in avoiding electrical safety problems, as well as one that is usable by your workforce, is a must. Management has to be aware of how decisions can effect safety. We’ll discuss making the right choices when identifying hazards, assessing risk and implementing risk controls. In this course we’ll look at real world scenarios and case studies and walk through the decision process. We’ll discuss the three legs of electrical safety; installation, maintenance and your electrical safety program. This course will prepare management personnel to administer their facilities electrical safety program.

Benefits

Updated For 2021 NFPA 70EWhat to look for at your own facility

Items With Calendar Requirements

Training required for your employees

Red flags to look for

Roadblocks to expect

Keys to success

Who Should Attend

Safety ManagersSupervisors

Field Supervisors

Foreman

Plant Managers

Anyone managing employees exposed to electrical hazards.

Covered:

- Testing & Troubleshooting vs Repair

- Live Work Permitted

- Energized Electrical Work Permits

- OSHA Safety Related Work Practices

- Training Required

- Retraining Triggers

- Elements of an Electrical Safety Program

- Who Are Your Qualified & Unqualified Workers

- Lockout – Tagout Program & Training

- Establishing An Electrically Safe Work Condition

- Verification Of ESWC

- Approach Boundaries

- Shock Risk Assessment

- Arc Flash Risk Assessment

- Arc Flash Boundary

- PPE For Shock

- Arc Flash PPE

- Arc Flash PPE Categories Method

- Arc Flash PPE Incident Energy Analysis Method

- Mitigating Arc Flash Hazards

- Care & Maintenance Of PPE

- General Maintenance Requirements

- Test Instruments

You must be logged in to post a comment.